Since prehistoric times, pottery has fascinated and been the livelihood of many inhabitants of Soufflenheim, an iconic Rhenish village blessed with naturally clayey soil. Even today, several families still offer traditional pottery and regularly admit visitors into their workshops to show them their ancestral art. Now it's your turn...

DISCOVER SOUFFLENHEIM POTTERY

As it progresses from the condition to rough clay to the kiln, Soufflenheim artisan pottery goes through seven key stages. Discover and admire unique Kougelhopf moulds and Baeckeoffe casserole cookware, products of a centuries-old craft.

Manufacturing stages

1. CLAY PREPARATION AND THROWING (SHAPING) PROCESS

It takes many years of practice to master the art of throwing to perfection. This is one of the most enjoyable stages to watch when you are new to pottery!

2. JOLLEYING

Using a mould and a shoe, the potter forms the object and gives it its final shape.

3. SLIP COATING

This word simply refers to the application of the background colour of the pot.

4. DECORATION

With hearts, arabesques, storks or daisies, the iconic flowers of Soufflenheim pottery, this painstaking step is essential for beautiful pottery.

5. DRYING

Quality pottery is dried in two stages: it is first quick dried on racks and then left to dry naturally over two to three weeks.

6. GLAZING

The potter dips the decorated side of the object in special coating that can be vitrified to give it a splendid glaze.

7. FIRING

Careful! The items are fired in a kiln for 7 to 9 hours, at 1000 to 1100°.

8. HEY PRESTO!

The object is complete, ready to be put on display in the shop to catch the eye of a buyer!

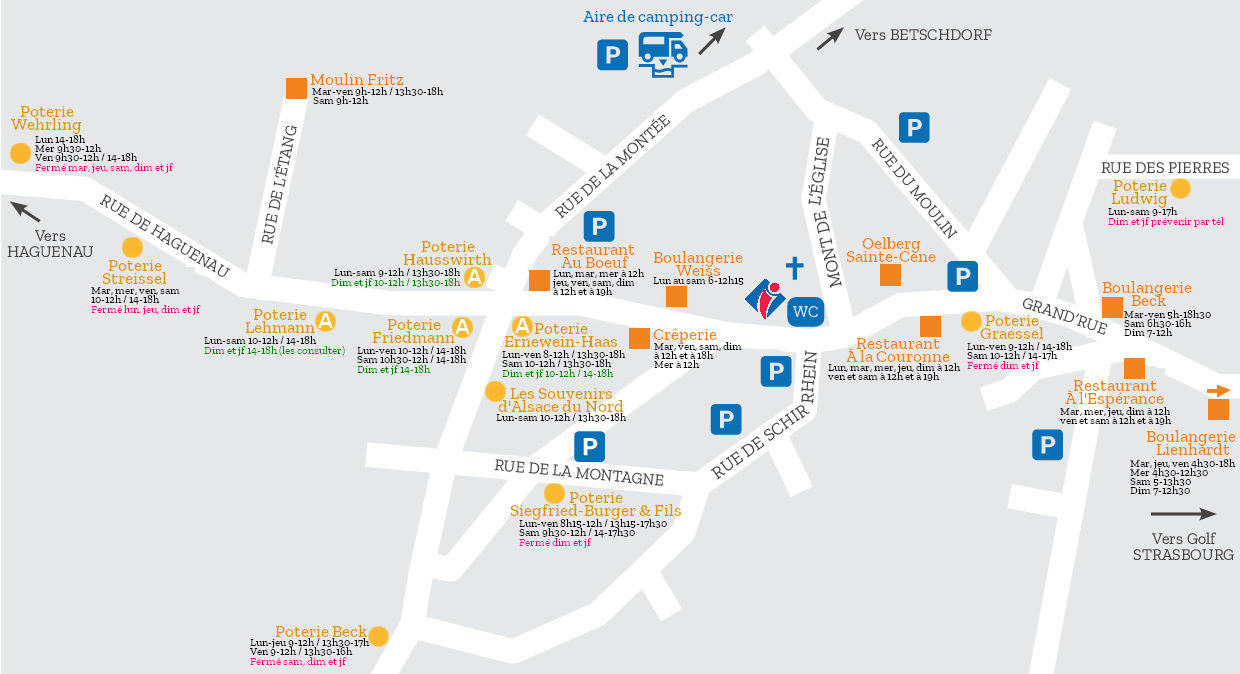

find your potter

Poterie Beck

Poterie Ernewein-Haas

Poterie Friedmann

Poterie Graessel

Poterie Hausswirth

Poterie Lehmann

Poterie Ludwig

Poterie Siegfried-Burger & Fils

Poterie Streissel

Poterie Wehrling